Focus on manufacturing chips with 28-nanometre technology demonstrates that India is ready to embrace advanced processes

Published Date – 3 March 2024, 11:40 PM

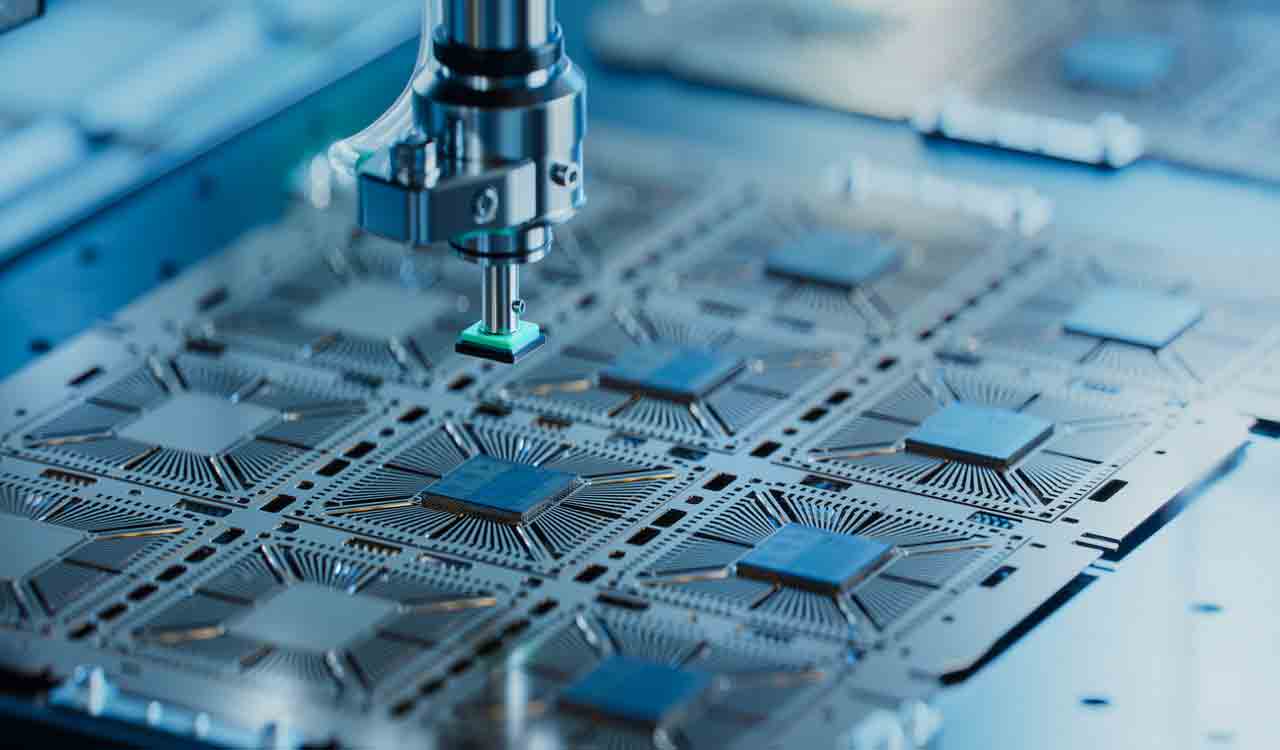

Representational Image

The Union Cabinet’s approval for setting up three semiconductor plants with an investment of Rs 1.26 lakh crore marks a major leap towards India’s ambitious goal to emerge as a global hub for chip manufacturing. The approved projects include the country’s first semiconductor fabrication plant to be set up by the Tata Group, in partnership with the Taiwan-based Powerchip Semiconductor Manufacturing Corporation (PSMC), in Gujarat’s Dholera at an estimated cost of Rs 91,000 crore. Another Tata Group proposal for setting up an assembly plant in Assam at a cost of Rs 27,000 crore has also been cleared, along with another one by CG Power in Sanand, Gujarat, which involves an investment of Rs 7,600 crore. These projects follow the government’s approval in June last year of Micron Technology’s assembly and test facility in Gujarat. The focus on manufacturing chips with 28-nanometre technology demonstrates that India is ready to embrace advanced processes and intends to compete on a global scale. In addition, reflecting a comprehensive approach to bolstering the chip ecosystem is the plan to modernise the existing facility — SCL (Semiconductor Laboratory) — in Mohali. The Centre aims to inject Rs 10,000 crore to make it an R&D and training centre in collaboration with a partner. Significantly, the Cabinet’s nod comes at a crucial juncture in view of supply chain disruptions due to geopolitical conflicts with nations across the globe keen on reducing their dependence on China. In a bid to boost the semiconductor ecosystem, the Centre had, in December 2021, unveiled a Rs 76,000- crore chip incentive scheme, offering fiscal support.

Though India traditionally had a strong base for semiconductor design industry, hardware manufacturing has remained elusive. Over the last two decades, several consortiums made multiple attempts at chip making but things never worked out. The global chips market is expected to grow to $1 trillion by 2030. Resource-intensive, it requires highly-skilled workers and is already facing a competence gap. Besides the US and Japan, India should also explore collaboration opportunities with other countries such as Taiwan and South Korea to promote domestic manufacturing and reduce import dependency. In the current geopolitical scenario, trusted sources of semiconductors and displays hold strategic importance and are key to the security of critical information infrastructure. As India embarks on its silicon journey, semiconductor job openings are set to rise. With its talent pool, India needs to leverage the opportunity and find ways to provide hands-on and industry-relevant training to engineering students. Taiwan provides a cue. Its success is attributed to public-private partnerships that focus on training and certification. As part of the $10 billion plan, unveiled by the Centre over two years ago, production-linked and design-linked incentives are being offered to companies to establish chip and display industries. Any country that does not learn to make semiconductors will lag behind others in the days to come.