Researchers of the Tata Institute of Fundamental Research, Hyderabad, have said they have developed a simple, scalable and cost-effective method to assemble a safer and durable Lithium Metal Battery

Published Date – 20 March 2024, 10:45 PM

Hyderabad: Researchers of the Tata Institute of Fundamental Research (TIFR), Hyderabad, have said they have developed a simple, scalable and cost-effective method to assemble a safer and durable Lithium Metal Battery (LMB), which is identified as one of the potential future storage systems.

The LMBs can provide nearly 10 times higher energy density compared to the current Lithium-ion Batteries (LIBs). However, they pose certain safety concerns and cannot be used for fast-charging applications. This is due to the uncontrolled dendrite formation, leading to excessive heating and battery short circuit, which has become one of the critical challenges of the LMB advancement, the researchers said.

To address these challenges, the TN Narayanan’s Lab at TIFR-Hyderabad modified the LMB using commonly available graphite derivative powder, increasing the battery’s longevity.

According to the researchers, a porous separator membrane lies between the electrodes in a battery, keeping them apart, and is crucial to preventing a short circuit. When a battery is used for some time, tree-like structures or whiskers called dendrites begin to form on one of the electrodes. If these dendrites grow uncontrollably, they may become a physical bridge between two electrodes, causing a short circuit.

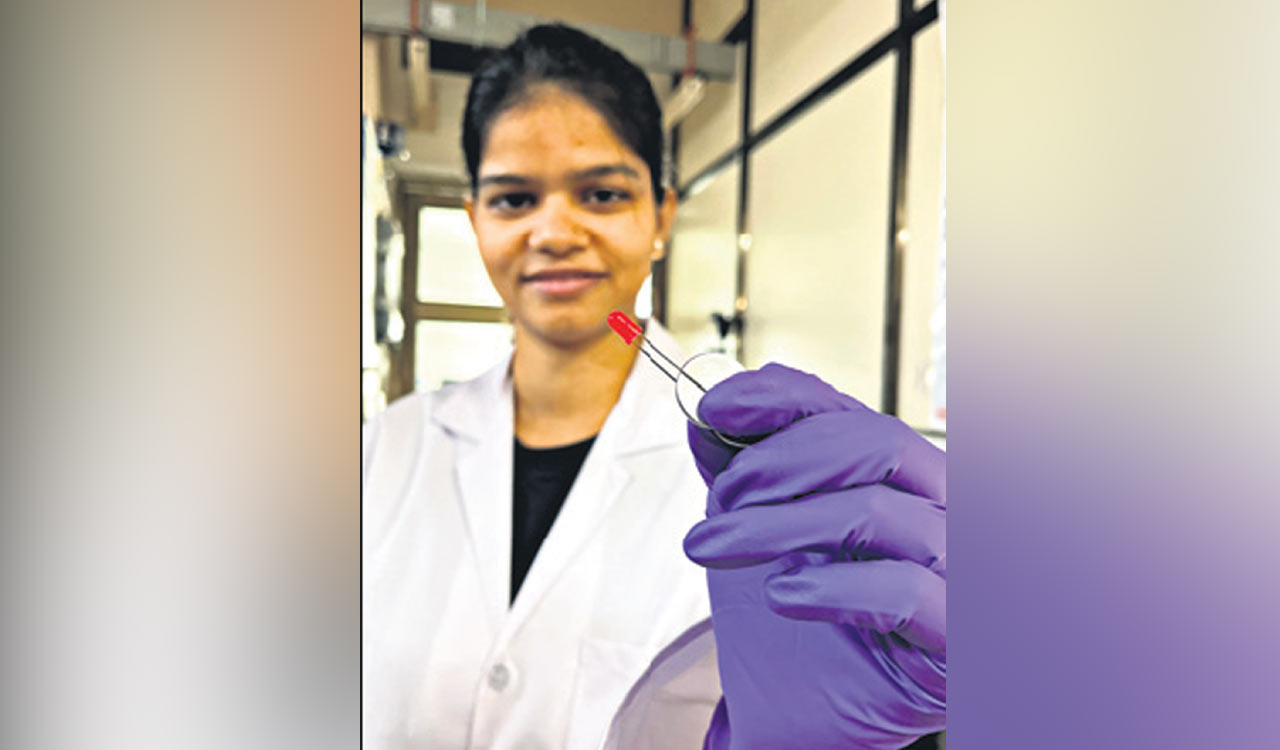

Preeti Yadav and Pallavi Thakur, graduate students and lead authors of the study, used commonly available graphite derivative powder to modify the separator membrane used in a typical battery. “This modification suppresses dendrite formation and improves the longevity of the battery to a large extent,” the researchers said, adding they proposed that this method of separator modification holds immense potential to be scaled up for industrial usage.

However, according to the researchers, at a very high current density of 10 mA cm-2, the battery seems to deteriorate slowly. This could be because of the electroplating of lithium on the carbon (a component of the deposited graphite derivative layer). The researchers aim to investigate these challenges further and understand the role of interfaces in improving the performance of a battery from a fundamental standpoint.